|

[Selective Soldering] 640.20

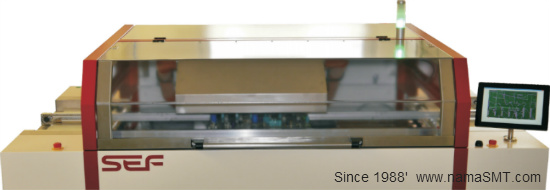

is a suitable selective soldering machine for small and medium volume production.

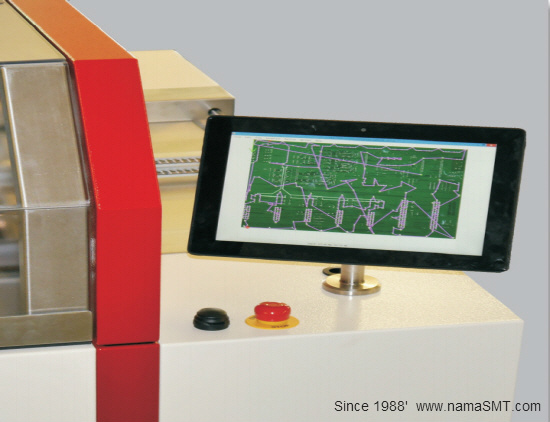

The 640.20 is a full-automatic selective soldering system for small and middle sized production lots. The system is operated with the help of a 7” tablet computer. The programming of the solder joints can be easily done by scanning the PCB and marking the required solder joints.

The maximum PCB size is 510 mm x 510 mm. The feeding of the PCBs takes place via a pin chain conveyor. Thereby the 640.20 can be used in batch mode (PCB feeding and discharge from the same side) or in inline mode (PCB is passing through the system).

A SMEMA interface is available for the communication with upstream or downstream devices.

A drop-jet dosing valve ensures the flux fill-up with high positioning accuracy. A light barrier is monitoring the presence of the flux stream. Afterwards the flux will be activated with the help of a preheating module with quartz glass IR heaters.

The soldering is provided by a low-maintenance electromagnetic pump and wettable solder nozzles under the supply of nitrogen. The soldering nozzles are available with different diameters. The movable solder pot has a controlled volume of 10 kg. If necessary more solder will feeded automatically.

The soldering can be watched with the help of a camera and a monitor. A lamp pole shows the status of the machine.

Feature

- Electro Dynamic Solder Pump without Moving Parts

- Height Measurement of the Solder Wave

- Offline Programming

- Electrical Working Width Adjustment

- Automatic Solder Feeding

- Camera Monitoring

- Status Message Lan or WLAN(op)

- Remote Controlling via Smart phone or Tablet PC(op)

- USB Interface

Details

|