| ▶

About Solderstar profile |

-

각 Solder Paste의 특성. Reflow의 Zone구간을 입력하면 자동으로 각 구간 별 온도 설정 값 을 알려준다.

또한 측정하고자 하는 PCB 혹은 피 형체의 사진을 입력 할 수 있으며, 각 Solder Paste의 특성. Reflow의

Zone구간을 입력하면 자동으로 각 구간 별 온도 설정값을 알려준다.

-

또한 측정하고자 하는 PCB 혹은 피 형체의 사진을 입력 할 수 있어 Data 분석에 매우 유용하게 할용할 수 있다.

스위스의 국제적 검사 대형 기관인 SGS 국제적 검사 대형업체에서도 Reflow 내의 온도측정장비로 사용하기도 하는온도

프로화일 이다.

-

Data 분석에 매우 유용하게 할용할 수 있다. 스위스의 국제적 검사 대형 기관인 SGS 국제적 검사 대형업체에서도

Reflow 내의 온도측정장비 로 사용하기도 하는온도 프로화일 이다.

|

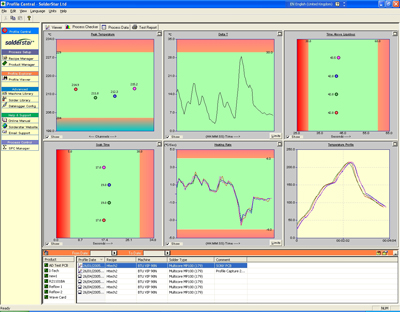

| ▶ Profile Central

Software - Simplicity Itself |

| In today’s world of advanced, high temperature,

lead-free electronics, the demand for thermal profiling systems that ensure

correct process settings are established and maintained is greater than

ever. However, for such systems to be truly effective, their software

must be easy to understand and use.

This is the philosophy behind SolderStar’s powerful and intuitive Profile

Central Software suite, regarded by many as the best available. It has

been designed to be user-friendly for both temperature profiling novices

and experts alike. Simple terminology, coupled with a heavily graphics-based

interface, allows users to quickly set up and analyse their reflow and

wave soldering processes.

SolderStar offers three thermal profiling packages, aimed at the different

technical and budgetary needs of low, medium and high volume lead-free

manufacturing, namely SolderStar Lite, SolderStar Plus and SolderStar

Pro. The Profile Central Software suite lies at the heart of all three

packages, with various additions as your requirements grow. |

Profile Central

Software Includes

- Product Manager

- Solder Paste Library

- Machine Library

- Profile Explorer and Viewer

- Profile Checker

- Profile Seeker

- Test Reports

- SPC Manager

- Wave Solder Support

|

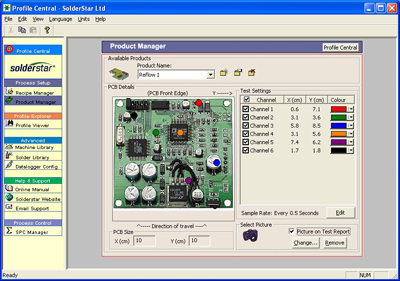

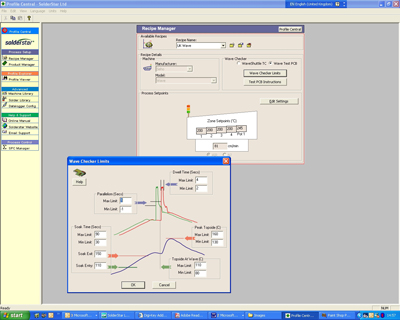

▶Product Manager

The exact profiling requirements for each separate

product you make can be tailored using the product

manager. Test card details, datalogger settings and

sensor attachment points can be recorded here both to

ease configuration of the system and also to record the

process. |

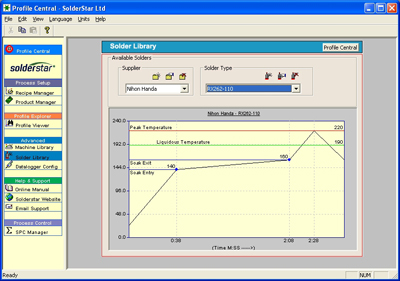

▶Solder Paste Library

Integrated solder paste library includes most of the

commonly used solder pastes. By selecting the paste

from the library, the user instantly sets process limits

appropriate to the paste manufacturer’s datasheet

recommendations. New, updated and speciality pastes

can be added using the solder paste wizard. |

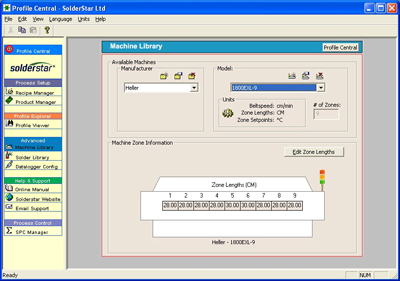

▶Machine Library

Integrated machine library includes many of the most

common machines in production today. By selecting the

machine from the library, the system is instantly set up

for profiling on that machine. |

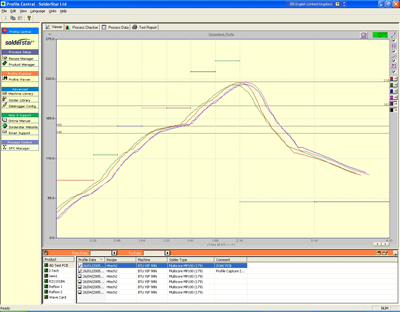

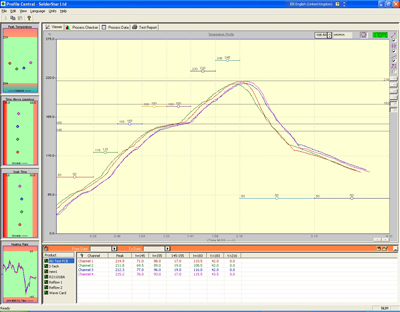

▶Profile Explorer and Viewer

The profile explorer allows you to store and organise your profiles effectively.

Downloaded profiles are automatically

stored in a database against the appropriate product. This creates a chronological

record of profiles for each product

and, along with searching tools, helps provide effective process traceability.

The profile viewer allows any profile in the database to

be instantly viewed. Manual measurements can be

made with up to four user cursors available. Profiles can

be customised by the free form annotation tools and

professional, comprehensive reports generated for hard

copy or emailing.

|

▶Profile Checker

The unique graphical profile checker takes the downloaded profile

and automatically calculates the process parameters of interest.

It then takes the relevant solder paste information from the solder paste

library and plots on easy-to-understand graphs how well each of the process

parameters is centred on the available process window.

Process evaluation is reduced to a single screen visual of good(green)/bad(red)

inspection.

|

▶Profile Seeker

If you have ever tried to adjust a reflow process on a multi-zone reflow

oven you will quickly have realised that there is a seemingly endless combination

of possible zone temperatures and conveyor speed setpoints.

Profile seeker is an offline simulation tool that allows the user to simulate

the effect of making multiple zone changes, combined with conveyor speed

changes, quickly and without impacting production.

The system shows both the effect on the temperature profile curve and the

process parameters with respect to the available process window. By avoiding

the usual ‘tables of meaningless numbers’ approach this highly

graphical approach allows the user to intuitively evaluate when changes

are making the process better or worse. |

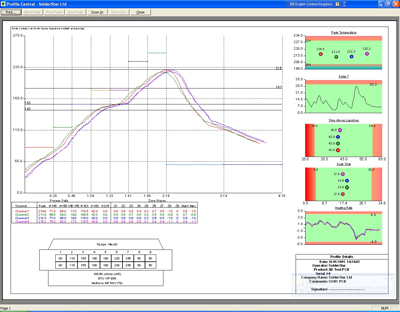

▶Test Reports

Professional, configurable test reports, containing

information about products, recipes and machine

settings, along with the temperature profile and process

checker graphs, can be generated at the click of a mouse.

Reports can be printed or emailed to remote customers

or remote sites. |

▶SPC Manager

SPC manager allows trends in the process to be

evaluated by way of rapid construction of Xbar and

Range charts. Profiles stored under each product in the

database can be selected and run charts are generated

with automatic calculation of Cp, Cpk and control limits.

Professional process charts can be generated for hard

copy or emailing. |

|

▶ Wave Solder Support

Profile central also includes tools for automatic

evaluation of the wave solder process. Whether you

are using your own wave test card or the inexpensive

SolderStar Waveshuttle Plus or SolderStar Waveshuttle

Pro test fixture, the tools extend rapid setup and

process control to the wave solder process.

|