|

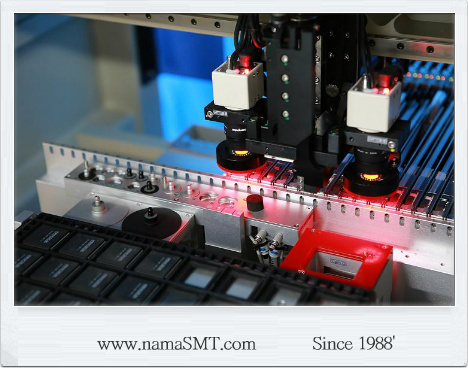

| 01005.0201 ~ CSP. uBGA 8000 cph . +.- 0.003mm Accuracy |

|

|

|

|

|

Product name

Product name |

BA 385V1/V2

|

|

|

Manufacturer

Manufacturer |

Autotronik-SMT |

|

|

|

|

|

|

|

|

|

|

|

|

|

사진으로 세부 기능 보기

정밀실장 01005 ~ u BGA Flat Chip

Solder Dispenser / Bond 동시 작업

1 or 2 head

Lab . Small Multi Product에 적합.

under vision

다양한 Nozzle 자동 교환

Pick up head에 Fly Vision 기본

IC Tray 기본 제공 Big Size IC 실장 가능

In line conveyor 기능 선택

Smart Feeder로 Pick up Error 극소화

다양한 Feeder장착 최대 127개 Feeder ( Conveyor 사용 하지 않을 경우 )

진통 Feeder Unit 장착

정밀 다품종 생산 적합장비.

가격 경제적인 장비

2개의 티칭 카메라 로 보다 빠른 Edit 설정

Module 생산 적합 장비.

초정밀 실장 장비

다양한 Application 가능

Conveyor table 2 type으로 PCB 설정

Feeder 교정 Setup station 기본 제공

원격 장비 유지보수기능 기본 포함 되어 있어

보다 빠른 유지보수

|

|

|

|

|

|

Small & Multi SMD Assembly machine

385 x

BA-385V2V SMT Pick & Place Machine Features

Speed, Accuracy and Precision

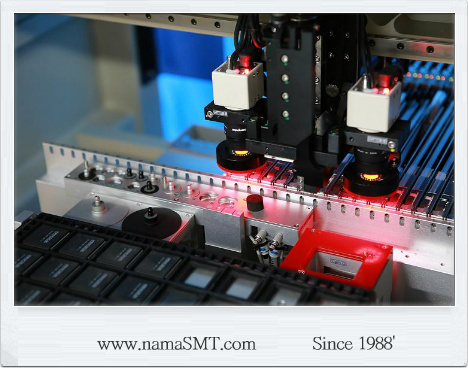

- 30 µm, 3 Sigma placement accuracy thanks to high-precision ball screw X-Y drive and closed-loop servo control system

- Heavy-duty welded, uni-body steel frame provides stability for precision placements even at high speeds

- Dual heads for placement rates to 8,000 parts per hour (5,500 pph, IPC-9850)

Huge Component Range

- Dual vision alignment combines Cognex® on-the-fly with bottom stationary systems for fast, efficient placement of 0201s through 100 x 150 mm SMDs

- 01005 placement capability available as option

- Full ball inspection and missing ball detection, with nonstandard ball patterns programmable and inspectable

- 15-position automatic tool holder/changer

Feeder Capacity and Flexibility

- Large placement area (from 370 mm x 350 mm (14.5" x 13.8") to 435 mm x 340 mm (17.1" x 13.8"), dependent on number of feeder bases and board handling method

- Holds up to four 32-port feeder racks for a total maximum feeder capacity of 128 8-mm tape feeders

- Feeder racks can accommodate a mix of tape feeders and IC tube/stick feeders

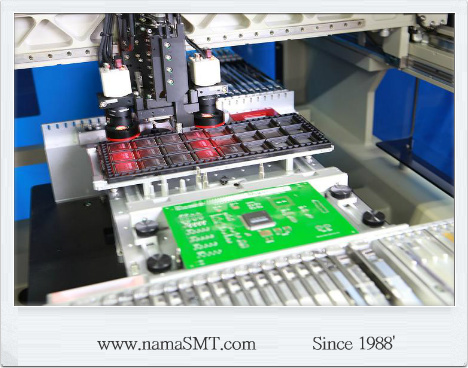

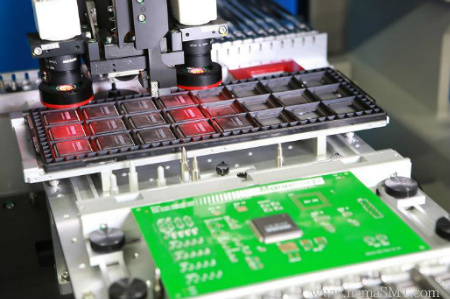

- Waffle trays and cut strip feeder holders can be used in placement area (one waffle tray included with machine)

- Suitable for any inline or work cell manufacturing environment: Batch configuration standard; in/out conveyor and SMEMA-compatible inline conveyor available

Easy Programming & Operation

- UCAD® universal CAD import and conversion for direct transfer of PCB data from ASCII, AutoCAD and Excel data formats

- Teaching/fiducial recognition camera

- Virtual PCB Simulator offers assembly preview for component, coordinates and orientation verification prior to running production

- Smart tape and IC tube/stick feeders for fast set-up and changeover and feeder placement optimization

Additional Touches

- Computer controller with flat-screen LCD display, keyboard and mouse included

- Included vision inspection capability allows camera to be used to selectively check solder paste printing or component placement accuracy

- Optional bar code reader scans component value, lot code, date and component quantities directly from component packaging for inventory management

- Optional offline Smart feeder programmer allows Smart tape and stick feeders to be programmed offline while the machine runs other jobs

- Optional temperature-controlled ATP digital dispensing system for solder paste and adhesive dispensing

Dispesner for Solder Paste or Bond

BA 385V is also available with an advanced time pressure (ATP) dispensing system. This high-accuracy dispenser with closed-loop, microprocessor control dispenses solder paste and adhesives at dot sizes down to 0.5 mm diameter at rates to 6,000 dots/hour. Dispenser option must be selected at time of purchase; due to its tight integration with the machine, it cannot be retrofitted.

IC Tray Station is standard.

Max Feeders 128 w.o Conveyor

Max Feeders 64 w. Conveyor

Work Area : 435 x 350mm w.o Waffle trays

Work Area : 435 x 210/150mm w. 1 or 2 Wafflie trays

OFF / in line Conveyor 2 type

Smalles 01005 ~ uBGA fine pitch Connector

Dispesner for Solder Paste or Bond

Fly Vison & Under Vision Camera.

1 or 2 head 4,000 CPH ~ 7,000 CPH

When you need to use Short strip tape.

|

SUMMARY

|

|

•

|

High Accuracy and high Flexibility for 01005, 0201, SOIC, PLCC, BGA, µBGA, CSP, QFP, up to fine-pitch 0.3mm |

| • |

Non-contact Linear Encoder System for high Repeatability and Stability |

|

•

|

Smart Feeder System provides Automatic feeder Position Checking, Automatic Component Counting, Production Data Traceability |

|

• |

Perfect for medium & high volume Production |

|

• |

COGNEX® Alignment System “Vision on the Fly” |

|

• |

Bottom Vision Alignment System for fine pitch QFP & BGA |

|

• |

Built in Camera System with Auto Smart Fiducial Mark Learning |

|

• |

Dispenser system |

|

• |

Vision Inspection before and after production |

|

• |

Windows XP Software |

|

• |

Universal CAD Conversion |

|

• |

Placement rate: 6,400 cph |

|

• |

Ball Screw Systems in X- and Y-Axes |

|

• |

Suitable for 128 intelligent Auto Tape Feeder |

The SMT Pick & Place Machines of AUTOTRONIK series were especially designed for medium and high volume batch sizes. Various models are provided for different applications.

BA385 is using KFTA series feeder same as the feeder used for our BS384, BS391 and BA683 AUTOTRONIK series Pick & Place Machines. By this means most reliability and easy maintenance for all models is guaranteed. Preloaded Ball Screws with Servo Motor system provides high Speed, Repeatability and Stability.

Additionally, the two "Vision on the Fly" alignment heads in BA385 are using Cognex® Vision System, providing high accuracy and easy learning for all different kind of components.

Dispensing Function

Detail

|

Strong and rigid mechanical design

BA385 using welded steel frame which guaranteed a strong and rigid mechanical design. Preloaded Ball Screws with Servo Motor system provides high Speed, Repeatability and Stability. |

|

Non-contact Linear Encoder System (Option)

By using „Closed Loop“ Servo Motors with non-contact Linear Encoder System, rovide extremely high Repeatability and Stability. |

|

|

COGNEX® Alignment System "Vision on the Fly"

The BA385 feature COGNEX® vision processing and head-mounted for non-contact „Vision on the Fly” alignment. The machine BA385 assures high-precision placement of the full range of SMDs, from the smallest 0201 devices through CSPs, µBGAs, flip-chips, ultra-fine pitch 0.3mm for QFPs, even odd-form components. |

|

Feeder Rack (FR-32K)

FR-32K is suitable for 32 x 8 mm KFTA Feeders or for 30 x 8 mm IC-Sticks (1x KFTB-2 / 1x KFTB-4). |

|

Bottom Vision Alignment System(Option)

A Bottom Vision Camera is used for large components up to 150 x 100 mm and devices with alignment features on their bottom side. Due to additional Bottom Vision Camera, the alignment of 01005 components is guaranteed. |

|

Smart Fiducial System

Beside the standard fiducial mark, either square SMD PCB pad or plate-through hole also can be trained as fiducial mark. For more precise placement of fine pitch components, additional Local fiducial recognition is provided. |

|

Universal CAD Conversion

Beside the direct input of data by teach-in camera, an optional CAD conversion program is available for directly transfer of CAD generated pick and place data. |

|

Auto Tape Feeder (KFTA)

The innovative design of KFTA feeder bases and mounting hardware allows almost limitless flexibility in feeder combinations and arrangement schemes, as almost every feeder can be ordered, loaded, programmed and mounted independently. KFTAs are available from 8 mm up to 72 mm tape width. |

|

Universal IC Tube Feeder

KFTB universal tube feeder are using vibration driven technique. It is able to handle IC-Sticks with max.50 mm width. |

|

Cut Strip Tape Holders (Short tape Staion)

Cut Strip Tape Holders is a handy accessory for present-ing components that are supplied in short lenghts of tape due to their low quantity of usage. It can also prevent the waste of components in sections of tape that are too short to be loaded into tape feeders. |

|

|

Dispenser System

Optional stand alone dispenser head for adhesive & solder paste dispensing. Perfect for quick, small volume production without making stencil. |

|

Conveyor System

The already included conveyor system with SMEMA Interface and motor-driven-width-control speeds up the handling of PCB and in-line production. |

|

Buffering Nozzle

The spring buffering design of Nozzle adjust the placement pressure for different heights of components automatically

|

|

Vision Inspection

With the built-in software, the camera can automatically move and display the image in the computer screen. User can manually check the printing accuracy of solder paste, quality of the soldering, accuracy of component placement, etc |

|

Remote Service Kit

Optional Remote Service Kit allows a remote access to machine by Internet, so that programming, calibration and service can be done by our worldwide remote service center. |

Features

Dual Vision Systems Cover Widest Range of Components

The head-mounted Cognex® camera provides true, non-contact alignment "on the fly" for the smallest parts, including CSPs and µBGAs, allowing for maximum speed and efficiency. Standard camera handles parts down to 0201s. 01005 capability is available as an option.

The other camera, a base-mounted, upward-aimed system, handles larger SMDs, including large BGAs, up to 100 x 150 mm.

Smart Feeder

|

|

|

|

|

|

|

SPECIFICATION |

|

1 |

Number of Heads

(Vision on the Fly) |

|

BA385V1 / V2 |

|

2 |

Placement Rate:

(under the optimum condition |

|

BA385V2: 8000 CP/H,

5500 CP/H (IPC 9850) |

|

3 |

Feeder capacity (8 mm)

without conveyor |

|

up to 128 Tape Feeders |

|

4 |

Feeder capacity (8 mm)

with conveyor |

|

up to 64 Tape Feeders |

|

5 |

IC Tray capacity |

|

up to 2 Waffle Trays |

|

6 |

Component Sense |

|

Vision detection |

|

7 |

Component Size |

|

Handled by head camera:

- Smallest: 0.6 x 0.3mm

- Largest: 16 x 14 mm

Fixed Bottom Vision Camera:

- Smallest: 0.4 x 0.2 mm (opt)

- Largest: 150 x 100 mm (opt) |

|

8 |

Resolution |

|

X / Y axis 0.005 mm Servo Motor

Z axis 0.02 mm Servo Motor |

|

9 |

Rotation |

|

0 to 360° (0,045°/step) Servo Motor |

|

10 |

Placement Accuracy |

|

+/- 0.04 mm

+/- 0.03 mm (by optional encoder) |

|

11 |

X-Y Repeatability |

|

+/- 0.01 mm |

|

12 |

Placement Area |

|

Feeder Rack front and back:

Max. 440 x 350 mm (w/o IC-Tray)

Max. 440 x 210 mm (with IC-Tray)

Feeder Rack from all four sides:

Max. 370 x 350 mm (w/o IC-Tray)

Max. 370 x 210 mm (with IC-Tray)

Feeder Rack front and back + conveyor

Max. 435 x 350 mm (w/o IC-Tray)

Max. 435 x 160 mm (with IC-Tray)

by optional PCB fixture

Standard PCB fixture:

For max. PCB size 270 x 350 mm

(w/o IC-Tray) |

|

13 |

Programming |

|

Direct input

Vision teach-in

CAD Access (Opt) |

|

14 |

Main Control |

|

Industrial PC |

|

14 |

Power |

|

230 V / AC - 2100 W |

|

16 |

Pressure |

|

75 psi (5.5 bar) |

|

17 |

Machine Size ( L x W x H) |

|

1200 x 940 x 1300 mm |

|

18 |

Weight |

|

450 kg

|

|

*기기사양은 기능향상을 위해 예고없이 변경 될 수 있습니다.

|

Strong and rigid mechanical design

BA385 using welded steel frame which guaranteed a strong and rigid mechanical design. Preloaded Ball Screws with Servo Motor system provides high Speed, Repeatability and Stability. |

|

Non-contact Linear Encoder System (Option)

By using „Closed Loop“ Servo Motors with non-contact Linear Encoder System, rovide extremely high Repeatability and Stability. |

|

|

COGNEX® Alignment System "Vision on the Fly"

The BA385 feature COGNEX® vision processing and head-mounted for non-contact „Vision on the Fly” alignment. The machine BA385 assures high-precision placement of the full range of SMDs, from the smallest 0201 devices through CSPs, µBGAs, flip-chips, ultra-fine pitch 0.3mm for QFPs, even odd-form components.(01005 chp) |

|

Feeder Rack (FR-32K)

FR-32K is suitable for 32 x 8 mm KFTA Feeders or for 30 x 8 mm IC-Sticks (1x KFTB-2 / 1x KFTB-4). |

|

Bottom Vision Alignment System(Option)

A Bottom Vision Camera is used for large components up to 150 x 100 mm and devices with alignment features on their bottom side. Due to additional Bottom Vision Camera, the alignment of 01005 components is guaranteed. PLCC.QFP. BGA. uBGA etc |

|

Smart Fiducial System

Beside the standard fiducial mark, either square SMD PCB pad or plate-through hole also can be trained as fiducial mark. For more precise placement of fine pitch components, additional Local fiducial recognition is provided. |

|

Universal CAD Conversion

Beside the direct input of data by teach-in camera, an optional CAD conversion program is available for directly transfer of CAD generated pick and place data. |

|

Auto Tape Feeder (KFTA)

The innovative design of KFTA feeder bases and mounting hardware allows almost limitless flexibility in feeder combinations and arrangement schemes, as almost every feeder can be ordered, loaded, programmed and mounted independently. KFTAs are available from 8 mm up to 72 mm tape width. |

|

Universal IC Tube Feeder

KFTB universal tube feeder are using vibration driven technique. It is able to handle IC-Sticks with max.50 mm width. |

|

Cut Strip Tape Holders (Short tape Staion)

Cut Strip Tape Holders is a handy accessory for present-ing components that are supplied in short lenghts of tape due to their low quantity of usage. It can also prevent the waste of components in sections of tape that are too short to be loaded into tape feeders. |

|

|

Dispenser System

Optional stand alone dispenser head for adhesive & solder paste dispensing. Perfect for quick, small volume production without making stencil. |

|

Conveyor System

The already included conveyor system with SMEMA Interface and motor-driven-width-control speeds up the handling of PCB and in-line production. |

|

Buffering Nozzle

The spring buffering design of Nozzle adjust the placement pressure for different heights of components automatically

|

|

Vision Inspection

With the built-in software, the camera can automatically move and display the image in the computer screen. User can manually check the printing accuracy of solder paste, quality of the soldering, accuracy of component placement, etc |

|

Remote Service Kit

Optional Remote Service Kit allows a remote access to machine by Internet, so that programming, calibration and service can be done by our worldwide remote service center. |

|

|

|

|

|

Option

1. In line Conveyor

2. Solder Dispenser System

3. Feeders

4. Short tape

5. Under vision

|

|

|

|

|