|

Model. 551-19 power 8.5A ~ 9A.

551-19 reflow is basically equiped with a mesh belt conveyor and 8 upper heating and 8 under heating zones.

It can be controlled individually.

As full air convection type and power energy saving product, 551-19 reflow oven of SEF GmbH provides high performance.

Max. temperature : 350 'C degree.

SEF GmbH in Germany which is a manufacturer of reflow oven, robot , laser remote and other industries has rich experience of development and production of welding equipment.

Also, SEF's equipment has below features.

551 seires is possible to realize IPC "JEDEC I,II" SPEC temperature.

Furthermore, eight of harmonized norms were observed for the design of the reflow oven.

Therefore, 551 series shows high durability, reliability and safety.

The additional upgrade of a soldering oven 551 series with the option 'Communication Package"allows a network connection of the soldering system via WLAN and LAN, WiFi.

An operation of the soldering system via WLAN is also possible with most of WLAN capable devices(Smart phone, Laptop, Netbook and so on).

It realizes safe, efficient and easy remote control.

l Up to 80% energy saving

l Individual Chamber Module

l Network. WLAN & Smart Phone. Dual Control.

l Board & Parts Detection

l Component Monitoring.

l Conveyor width 405mm.

l Built in temperature Profiler and record and analysis function.

l 7 inch Full touch Panel.

l Various Interface : SMEMA . PC . & WLAN. WiFi. PDF printing

l Individual painting at customer request

551 Series Reflow

551 series has three models like as 551-10/15/20

Each function and feature is same but only the length of the conveyor is different depending on the model.

551-19 Model offers 8 zone reflow oven.

|

Model |

Heating zone |

ChamberLength |

Conveyor Width |

Dimension (L.W.H) |

|

551-15 |

5 zone |

1060mm |

405mm |

2010 x 790 x 550 |

|

551-19 |

8 zone |

2200mm |

405mm |

3400 x 790 x 1268 |

Main Application Field

: Mass product, SMD parts reliability (PCB, FPCB, Semi-conductor, LED, Device)

laboratory, QC, industry academic cooperation, University, small and multi product

Chamber Module (Modular configurable)

Via modular heating chamber, 551 series soldering system offers easy maintenance and efficient control.

Furthermore, the scalability of the heating chamber is very high.

Module Heating Chamer is good for scalability.

Various Interface Control

551 series soldering system can control by not only 7" touch panel but also smart phone, tablet PC or Laptop which can be control via WiFi, WLAN orUSB Port.

To control the machine, you can download an app directly on your smart phone.

The free app makes the machine to do dual operation.

Also, via SEMEMA data, you can manage the machine efficiently.

The various ways to data printing

The data of parameter and temperature profile can be saved at the machine directly, PC or USB storage.

The temperature profile which is stored at USB storage can be stored at PC.

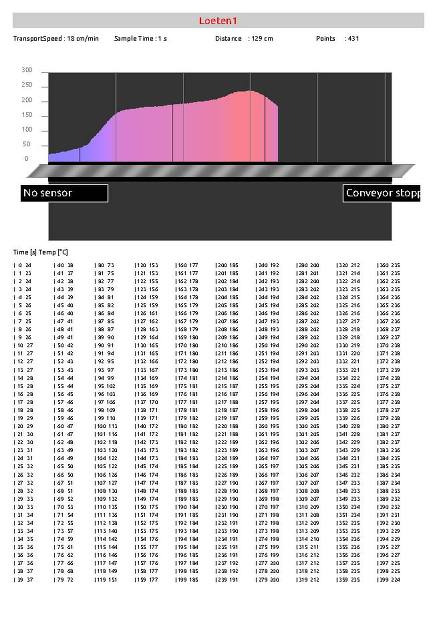

Especially, the temperature profile is saved as pdf file automatically. Please refer below picture.

The saved pdf file is able to be converted as MS excel. The saved pdf file is able to be converted as MS excel.

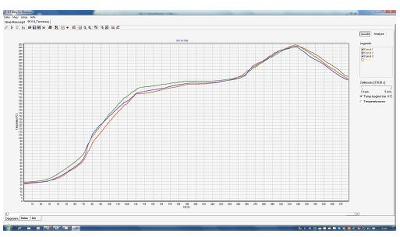

Please refer below picture which shows profile graph and data value per second.

Other Data

Profiler Data

551-19 diagram

|